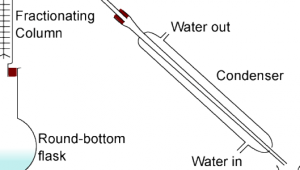

Fractionating and reflux stills are very similar in nature. They both aim to make a more pure distillate in a single run. As the wash boils the steam travels up the column. Some components recondense (reflux) before they reach the condenser and flow back into the boiler. This makes the cuts between the head, hearts and tails more distinct as well as making the distillate higher in alcohol (ABV). These types of stills are generally used to make vodka and other neutral spirits which will later be flavored or blended with other ingredients.

Reflux Still

Copper Mesh

While the two types of stills are similar you can achieve some reflux by packing the column between the boiler and condenser with marbles (yup, marbles), ceramic pieces, copper mesh or anything else that the vapors can condense onto. You can also get some reflux to occur by tilting the lyne arm of a pot still up at 45 degree angle allowing the vapors to condense on the walls of the lyne arm and flow back into the wash. Reflux stills tend to have a shorted column than a true fractionating still.

Fractionating Still

A fractionating still works the same way as a reflux still. However, the column in generally much longer, 3’-6’ and even longer in large scale operations. Instead of the column being packed with copper mesh or other materials this still has a fractionating column. This column has horizontal plates that allow the vapors to condense and flow back into the wash while other vapors make their way to the condenser and get collected.

A good Fractioning Still has more than one take off and the temperature at each take off is controlled so that only one fraction condenses at each level. Hence Ethanol can rise to the top and be taken off separate from Ethanol which comes off in the second position and Isopropyl in the next lower position. Getting rid of the Isopropyl will get rid of the hangover effect. The water and the Tert Amyl come off on the bottom. This type of fractioning still is used when the wash is introduced on a continuous basis and everything is boiled. This is exactly the way a cracking tower works in the Oil Industry.