Making Whiskey is not complicated. It consists of five basic steps which we will look at detail. However, before you begin read this entire article, read the safety tips below and ask questions if there is something you do not understand.

A Little Safety Before You Begin

- Ethanol is Very Flammable!!!

- Check equipment before each run. Make sure seals are good and the still has no cracks, holes, leaks, etc.

- Still should be run in a well ventilated location.

- Have a fire extinguisher close and available.

- Never leave a running still unattended.

- Do not allow vapours or liquid product to be exposed to open flames of heat source.

Here are the 5 steps we are going to follow. We will discuss each in detail.

- Making the Mash aka Mashing

- Fermentation

- Distillation

- Aging and Maturation

- Dilute and Bottle

While there are many types of spirits that can be produced from the distillation process we will focus on Whiskey. Each distilled beverage has its own recipes and distillation techniques. For example, Vodka is generally produced from potatoes or rice in Eastern Europe. When it is distilled if must be refined to 96% Alcohol by Volume (ABV) thus removing any flavor from the distillate making it a neutral spirit. Before bottling the Vodka is diluted with water to give it the legal EU minimum ABV strength of at least 37.5%. Whiskey on the other hand is distilled to no higher than 80% (ABV) so the flavors from the mash are part of the distillate.

So, what is Whisky (Scottish, British and Canadian English) or Whiskey (Irish and American English)? Whiskey is made from fermented grain mash. Different combinations of grains account for the different varieties and flavors in Whiskey. Generally the mash is made from malted barley, rye, wheat, and corn (corn being the main ingredient, 51% or more, in Bourbon Whiskey). The whisky is then aged in Oak barrels. The inside of the barrels are ‘toasted’ which is what imparts the caramel color to the end product. All whiskey is normally aged for a period of time in barrel with the exception of corn whiskey which does not have to be aged.

OK, enough already! Let’s make some whiskey.

Step 1: Making the Whiskey Mash

What is Mashing? Mashing refers to the hot water steeping process which activates malt enzymes and converts the grain starches into fermentable sugars. At this point you have a sugar rich solution called the ‘wort’ (pronounced ‘wert’). Yeast will convert the wort to alcohol.

Now you must decide what you want to make. There are many whiskey recipes available and each has its own distinct quality and flavor. So, experimentation and good note keeping will help you figure out which recipe is right for your intended purpose. Here are a few recipes to get you started.

Depending on the recipe you may need to transfer the wort to another container (fermenter) for fermentation. Once the mash has been prepared according to your selected recipe proceed to step 2.

Step 2: Fermentation

Fermentation: The biological process in which sugars such as glucose, fructose, and sucrose are converted into ethanol and carbon dioxide (CO2).

Once you have picked your recipe, made your wort and pitched the yeast the wort will start to ferment. This process can take anywhere from a few days to a week depending on the type of yeast, temperature of the ferment and nutrients available to the yeast. There are a couple ways you can determine if the ferment has finished.

- Wait till you are not seeing any little bubbles being formed. You will see this at the top outer edge of the fermenter. If you are using an airlock wait till it stops bubbling and then give it one more day to rest. This is a rather crude way to determine the completion of fermentation.

- Use a hydrometer.

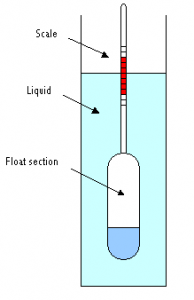

A hydrometer measures the density of a liquid relative to water. An in-depth discussion on hydrometers can be found in the article “What is a Hydrometer.” One easy way to tell if fermentation has completed is to take a reading 1 time per day for 3 days. If the reading on the hydrometer stays the same, fermentation has finished. Here are a few tips for using the hydrometer.

- Take a sample of the fermented wort using a turkey baster or wine thief. Put this sample into a graduated cylinder.

- Gently lower the hydrometer into the graduated cylinder.

- I like to spin the hydrometer gently to free it of any bubbles that might interfere with the reading.

- Read the number on the hydrometer that is at the water line.

Now that fermentation has completed we can move on to step 3.

Step 3: Distillation

Distillation: Method for separating mixtures based on differences in volatilities of components in a liquid mixture. This applies to the production of essential oils, gasoline, and of course in our case, ethanol (alcohol). Our goal is to separate the ethanol from the fermented wort. We are not going to get a 100% ethanol solution. We are instead trying to get an 80% ethanol solution with the other 20% being comprised of water and flavors from the mash.

Whiskey is generally distilled in what is called a Pot Still. A discussion on stills can be found in the article “Moonshine Stills”. Here are the basic steps needed to distill the fermented wort:

- Transfer to Still: Siphon or strain the fermented wort (aka ‘wash’) through cheese cloth into the still. The cheese cloth is only used to take separate the large solids. If you are siphoning the wash into the still try to leave behind the solids at the bottom of the fermenter. Once again no worries if some solids get transferred.

- Assemble the Still: Assemble the rest of your still according to the manufacturer’s instructions.

- Heat\Boil: Heat the wash slowly. The goal here is to not burn the wash. Give yourself 30-60 minutes to bring the wash to a boil. Usually a medium to medium high temp is adequate.

- Start the Condenser: There should be a thermometer located just before the cooling condenser. When this reads 120º F- 140º F (50º C-60º C) start the cooling water for the condenser tube.

- Heads Out: A steady drip should start to flow from the end of the condenser. For a 5 gallon wash throw out the first ¼ cup (~50 ml). This portion of the ferment is referred to as the heads. It contains methanol and some off flavors that you do not want in your final product.

- Body In: Continue fermenting collecting the distillate in 500ml portions. This is the good stuff. The thermometer just before the condenser should read somewhere around 175º F-185º F (80º C-85º C).

- Tails Out: When the thermometer start to climb to around 205º F (96º C) you are starting to distill out the tails (aka fusel oil). These will add off flavors to you final product and should not be mixed with the body.

- Clean Up: Turn off or remove the heat source. Turn off the cooling water. Let everything cool and then clean thoroughly.

Step 4: Aging and Maturation

Whiskey is best when it has been aged for a period of time. Aging normally takes place in Oak barrels. However, you can also add oak chips to the whiskey and let age. Keep in mind that whiskey only ages in the barrel. Once bottled the flavors will not change and mature. Aging makes the whiskey smoother and adds an oak flavor to the final product. The whiskey should go into the barrel somewhere between 58%-70% ABV. Bourbon whiskey must not enter the barrel at more than 62.5% ABV if it is going to be called a bourbon whiskey.

Step 5: Dilute and Bottle

In order to enjoy a glass of whiskey you need to cut it with water. Drinking spirits at 75%-80% ABV can be an uncomfortable experience. Generally whiskey is diluted to 40% ABV (80 Proof). Once diluted it is immediately bottled, labeled and enjoyed (not necessarily in that order).

Forty years ago my dad made his own whiskey with a Sears water distiller, I was in the Navy and never seen any of his recipes or notes on the use of the distiller. He past on before i could talk to him about it, Any comments?

why not just use a sugar and water mix to make the mash and bypass most of the mashing process. You only need to ferment and distill from there.I havn’t read a lot of detail about filtration. Do you use activated carbon or hardwood charcol in the filter?

if you use water and sugar as your mash that is new age vodka. you can make it taste like whiskey by adding a flavor infusion, but thats it. you need the grain to give the whiskey the real flavor.

when your distilling and your tempature starts to rise to 205 you said it starts to produce tails. now does the tempature randomly rise from the set tempature by itsef? is this the only way to tell that you are producing this tails.

What happens is while it’s boiling off the ethanol at around 172, it will eventually run out of ethanol to boil, at which point it moves to the water. That’s why even though you have a constant heat temperature, it will move from around 158 for methanol, to 172 for ethanol, then to 212 for water. I’m sure someone with a little bit of a chemistry background could elaborate more on how this happens…but that’s why the temperature rises on it’s own, it’s boiling off each product.

ragman

if i have a 5 gallon still and 50 gallons of wort, when and how do i add more wort to pot

You have to make multiple runs. You would add about 4 gallons to the still. Run the still. When that batch is complete, empty the still, add 4 more gallons and do it again.

How or where can I learn to make my own barrels. The talk of aging whiskey has me curious if an average joe could learn.

These folks have a class in Coopering Barrels. Not sure where you live but this could be a fun trip – http://www.tillersinternational.org/woodworking/classes_448_cooperingbarrels.html

how long should i age it? i’m not trying to do the best whiskey on earth but just trying to catch on a reasonable taste. What is the minimum time for this?

Flavor\color extraction is faster in smaller barrels. So, if you age in a small 1 liter oak barrel it will only take a few weeks to get a nice color and some good oak flavor. Larger barrels will take longer.

Here is one you might want to try…

Oak Beverage Dispensing Barrel with Brass Bands: 1 Liter – Whiskey

can you make a flavored moonshine and still have 100 proof alcohol? If possible, could you give me any tips or ideas.

Sure. You can add all sorts of things to moonshine. One way is to add fresh fruit directly to the moonshine and let sit for a month or 12. Filter out the particles and enjoy.

There are also food grade flavorings you can buy. Or you can make your own syrups.

I made a brandy and added some wine grapes to the jar. The berries added a nice color and mild flavor and sweetness to the final product.

Just experiment and see what you come up with. Oh ya, if you come up with something you really like please share with the group

I just started researching all this…is there a reason why everyone uses oak chips? can I use cherry, apple etc??

thanks!

Oak has traditionally been used because of its ability for it to be worked in staves for barrels and it has a very tight grain. The tight wood grain in oak makes the extraction of oak flavors more gradual and also keeps more oxygen out. In wine making oxygen is the enemy of wine. With whiskey more distillate will evaporate (the angel’s share).

However, if you are adding in wood chips we do not need to worry about the above issues.

Here is a link to an article about aging in different types of wood.

+++++++++++++++++++++++

To date, most of the studies examining the influence of wood aging on wine have focused on French and American oak barrels, which are undoubtedly the two most common types of wood used in this type of aging. These types of barrels have been used for generations, and are the traditional woods of choice when aging wine or other distilled beverages. However, more and more alternatives to the traditional French and American oak barrels are being used, partly for variety, but more importantly for cost-savings. These alternatives include chestnut, acacia, cherry, and ash (to name a few); all of which cost markedly less than traditional French or American oak barrels, and also give unique sensory characteristics to the finished wine which are becoming more desirable among consumers.

+++++++++++++++++++++++

I have also seen folks talk about these other woods giving an off smell\flavor. However, the best thing to do is make a small test batch and add different types of woods to see what you like. At the end of the day it is about what you find pleasing in the end product.

Hope this helps.

thanks for the great answer!!

how well ventilated does the area need to be?

Well, this is an interesting one. Most still makers will tell you that the area should be well ventilated so alcohol vapors do not accumulate. However, a still is turning all the vapors back into liquid during its operation. I guess it also depends on how you are heating the wash. So, how well ventilated should the area be? I would say about as well as your kitchen.

I reside in Texas (not that it matters except for the question at hand) and want to take up distilling whiskey for personal consumption, but am not sure what the regulations are. If brewing your own beer is legal, can I LEGALLY distill my own whiskey without fear of Kevin Costner and Sean Connery using an axe to bust up my still?

It is illegal to distill alcohol in the USA. You can make your own beer, you can make your own wine. However, once you put it into a still…you are breaking the law. Take a look at this post…

http://howtomakewhiskeyhq.com/is-it-illegal-to-make-whiskey-part-1/

You can get an alternative fuel license or a research license to distill legally. But keep in mind that the license will also determine how the distillate can be used,

You need to check with each state.

This is where I found a list of state by state laws. If in doubt about what you are reading with these laws, your best bet would be to contact a lawyer.

Wait will you are not seeing any little bubble being formed.. What did you mean to say?

First off, thanks for point out this passage as it had some spelling\word selection errors 😐

When you see bubbles it means that the yeast is still metabolizing the sugars and releasing CO2. This is what is causing bubbles to form. When there are no more bubbles it can be assumed that fermentation is complete.

Hope this helps.

Great info!! In the aging process – for example – if I put oak chips in the alcohol and let it sit in an airtight container for a period of time will that give me the same effect as aging in an oak barrel? Or does the aging process have to happen in an oak barrel. Also any idea what adding a little filtered charcoal to the air tight container will do to the final product.

Adding oak chips is something that is common for home brewers and winemakers. So, yes, this will give impart the oak flavor in the whiskey. Make sure you use American Oak.

You can also add a limp of charcoal to the batch. make sure it is a hard wood charcoal and does not contain anything other additives, etc. You will want to let this sit for a year or so. Make sure you filter before you bottle.

Here are few resources that may help…

For five gallons of fermented wort, how much total distillate should I expect to collect?

This depends on a couple factors.

1) What is the percentage of alcohol of your wort?

2) The efficiency of your still

So, let work with some easy numbers. If I have 10 Gallons of wort and it is 10% alcohol (ethanol) this means I have 1 gallon of ethanol. If your still could separate 100% of the alcohol from the water you would have 1 gallon of ethanol. There are a couple issus with this calculation. First of all your still, no still, is that efficient. Also you cannot separate all the water from alcohol. OK, here comes a little chemistry lesson. So, when you asked your chem teacher when you would ever need to know this stuff…it’s now :-). When you have 95.63% ethanol and 4.37% water by weight you have what is called an azeotrope. The problem with this is that water has a boiling point (bp) of 100° C and ethanol bp of 78.4° C. The azeotrope of water and ethanol has a bp of 78.2° C. So, this makes it impossible to separate the water from ethanol by standard distillation methods. OK, that was probably more than you wanted to know. Back to the question. If you have 10 gallons of wort at 10% alcohol and your still on the first run will make a 50% (100 proof) product you will have approximately 2 gallons of 100 proof whiskey.

(Gallons of Wort)(Percent ethanol of wort)/(Efficiency of still)

for our example above this would be…

(10 Gallons)(0.10 Ethanol)/(0.5)=2 gallons

Keep in mind that this is a rough calculation but should work for your purposes.

Happy Moonshining!

Maybe I missed something in your equation joeseph, but 10x.1x.5 comes out to .5 gallons on my calculator.

You have to divide by 0.5 not multiply.

Example….

If you have 10 gallons of wort at 10% alcohol there is about 1 gallon of pure alcohol.

(10 Gallons)*(10% ABV)=1 gallon of alcohol.

If your still is putting out a 50%alcohol distillate then you will have 1 gallon of alcohol and 1 gallon of water.

Hope this helps.

is the wort the same process to make beer…so is whiskey/bourbon beer before the final product. thanks, Jay

For the most part yes. The ingredients are basically the same. Even the person making the mash and doing the distillation is called the “Brewer”.

Both Whiskeys and beer start out with the ‘same” process but neither is ever the other.

Beer is largely produced from barley grains (but not always). Barley is not generally the main ingredient in whisky – corn, rye and wheat are. Since the Japanese make rice beer i will give you this piece of the argument.

Beer is also differentiated by the allowable alcohol content. For the sake of argument you could make a case that in the fermenting process the alcohol content goes through the allowable volume for beer. You reluctantly get another piece.

Beer also requires a carbonation process or in some cases nitro.Without some form of bubblicious gas the fermented beverage is not beer. But as you know whiskeys are not carbonated, so your argument doesnt hold and i have to strip away your 2nd piece just because.

.