Pot still were one of the earliest still types used to separate ethanol from fermented mash (wash or wort). It is the modern descendant of the alembic still. Pot still are simple and somewhat inefficient for separating alcohol from wort. This is both good and bad. If you are trying to make a neutral spirit with no flavor and yield the highest alcohol content possible then a pot still is not the correct tool. Instead a reflux still may be the better option. If you are looking to produce an end product that is lower in alcohol, ~80% or less, and retain the flavors of the original fermented mash a pot still is perfect. This is the main difference between beverages like vodka and whiskey. Vodka has little to no flavor whereas whiskey has much more flavor and complexity. In addition to the way the wort is distilled, each mash recipe will have its own characteristics when distilled. This is one of many parts of the process where a whiskey maker can distinguish their product from others. Bourbon whiskey for example is made from a minimum of 51% corn whereas American rye whiskey is made from at least 51% percent rye. Each of these grains will expose their particular quality in the end product.

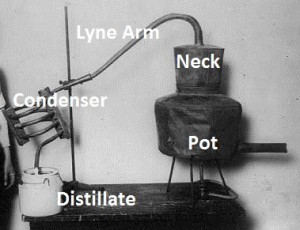

Anatomy of a Pot Still

The pot still has four main parts: The pot, neck (swan neck), lyne arm and condenser. The shape of the pot, angle of the lyne arm, condenser length, etc. will affect the flavor of the final product. This is another area where the brewer has the ability to create a distinct style of their own.

Pot: The shape of the pot is generally a cylinder that is wider at the top than the bottom. The pot is filled with the fermented mash and heated with fire or an internal heating mechanism. Most commercial distilleries heat the wort (aka wash) with 400 degree steam pumped through tubing that is coiled inside of the pot.

Swan Neck: The neck allows the vaporized alcohol and some water\flavor to rise up and enter into the lyne arm. The neck is often narrower at the top than the bottom allowing for non-ethanol components to condense on the walls and fall back down into the wash. However, as you have probably noticed this is not how the still in the above image is configured. This just demonstrates the vast amount of variation in each design.

Lyne Arm: The lyne arm will affect the amount of non-ethanol components that make it into the distillate. For example, as the vapors rise up the neck and into the lyne arm the temperature becomes cooler and the less volatile compounds (water, flavor, etc.) will change from a gas state to a liquid state (condense). If the lyne arm is ascending at a 45 degree angle those compounds will flow back down into the wash. This will give you a ‘lighter’ flavor and higher alcohol content in the final product. On the other hand if the lyne neck was angled down at a 45 degree angle the less volatile compounds will condense and drip down into the condenser, along with the ethanol vapors thus giving the distillate a more flavorful, ‘fuller’, taste.

Condenser: The condenser cools the ethanol vapors to a temperature that is less than their boiling point. Thus, it condenses the vapors back to liquid. Condensers can be cooled by the ambient air temperature, flowing air (a fan) or water. With a water-cooled condenser the cold water will be pumped through a coil, as in the diagram below, or around the outside of the tube that carries the ethanol vapors. Different designs will utilize different methods. The key is to cool the vapors so they drip into a collection container as opposed to escaping into the air.

It is up to the distiller to experiment with different mash recipes, still shapes and configuration to produce the end product that has been envisioned. Bottom line: Take notes, take your time, have fun and experiment.

The real idea of a thumper is to catch any boil over(puke) and keep it out of your hooch

Sounds like you are referring to a Slobber Box. The Slobber Box is similar to a thumper, However, the inlet of the thumper directs the steam to the bottom of the container which is partially filled with heads or mash. This acts like a secondary distillation increasing the alcohol content of the distillate.

Slobber boxes do not bubble the steam through liquid. The idea here is that it helps separate the congeners (puke) from the end product.

I just recently purchased my own still from here, it’s a wonder, great craftmanship and very beautiful! I’m even having twice thoughts of using it lol I’m on my first batch and just waiting for it to fully ferment. I’ve seen some stills that have this so-called thumper (mine doesn’t have one), I don’t think you discussed that in this article. Is this thumper necessary? How will it affect my moonshine or whiskey? Thanks.

The thumper is not necessary. The idea behind the thumper is you can get a higher ABV percentages with each run. You can achieve the same results by running the distillate through the still a second or third time. Either way you will most likely cut the whiskey with water to about 40% ABV. Your first run through your still, your very beautiful still, should produce a product around 60% ABV.

Happy Moonshining!