This corn whiskey recipe is a little more involved because the corn needs to be sprouted. However, the end product and the entire process is very satisfying as there are many interesting tasks that are needed to make this very special corn whiskey.

Ingredients:

- Whole untreated kernel corn, 10 lbs. (4.5 kg)

- Water, 5 Gallons (~19 L)

- Champagne yeast (Refer to manufacturer’s recommendations for quantity)

Equipment:

- Burlap sack. Yup…a burlap sack.

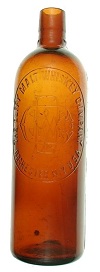

- Mash Tun (Fermentation Container): 6 Gallon food grade plastic bucket, copper barrel, etc. Do not use a carboy because the small opening for filling will prove to make things difficult.

Note: Do not use an aluminum container to make your mash!

Directions:

- Place the whole untreated corn kernels into the burlap sack. If you like you can divide the corn into two burlap sacks if this will simplify handling.

- Pour warm water into the burlap sack making sure that all the corn is wet. One option is to place the sack of corn into a bucket while pouring the water.

- Put corn bag in a warm, dark location. In about 8-10 days sprouts will protrude from the bag.

- When sprouts are approximately ¼ inch pour the corn into a bucket of water. Using your hands stir and agitate the corn removing any sprouts or roots which can be discarded.

- Put corn into the primary fermenter and crush the kernels so all of them have been cracked open. This can be done with a solid rolling pen, pipe with a closed end, etc. Get creative here.

- Add 5 gallons of boiling water. This will help convert some of the corn starches to fermentable sugars.

- Let mash cool to around 86º F\30º C and then pitch the yeast.

- Ferment. This will take anywhere between 5-10 days depending on yeast, temp and available nutrients.

- When fermentation has completed strain or siphon mixture into still leaving behind as many solids as possible.

I see whisky recipes made wit “sweet feed”. What are your thoughts on this mixture?

Malt corn makes the finest green drinking whiskey there is, very smooth,the aroma is wonderful and carries very little to no hangover at all. while drinking it appears to have very little alchol content whatsoever. however, when the individual tries to stand, he finds himself,VERY DRUNK. Malt corn mash mash should never have sugar added as it tends to make the whiskey a lower grade of alchol. the malt corn yield is very low, appx.3.5 gallons for 50 gallons of mash, but in 3 yrs, aged in wood, the finest Burbon in the world in every way, smell and taste. The older it gets the better it is ! !

Why not use field corn when it is being harvested, I use it for Whiskey, and Deer feed.

How much whiskey will this recipe produce?

Question: Is there a certain amount of time after a mash has become ready that it must be run off? Will the mash turn bad after a period of time?

Short Answer:You should run your mash within a week or less of finishing ferment because it will start to go bad.

OK, here is the long answer. The mash is loaded with all sorts of critters like wild yeast, bacteria, etc. If the mash is boiled before pitching the yeast AND put into a sterile fermenter AND you keep the lid on without peeking AND you store in a cool place after fermentation is complete it could last for some time.

We have wild yeast and bacteria all around us. If we don’t utilize some method that keeps these organisms at bay they will start to metabolize other components in the mash thus making it go bad. In wine making Potassium metabisulfite, K2S2O5, is used to kill unwanted critters and preserve the wine. In beer making hops acts as a natural preservative.

++++++++++++++++++++++++++++++++++++++++

Hop Acids are currently being successfully used as preservatives in processed meats and various food products. As with beer, Hop Acids have a place in the preservation of various beverages.

Source: http://www.usahops.org/graphics/File/Lloyd_Schantz.pdf

++++++++++++++++++++++++++++++++++++++++

I really look at the fermentation process as a race between the good critters VS the bad ones. We want to have an environment for our good yeast to outperform the other yeasts and bacteria in the wash.

Hope this helps.

Thanks, yes it helps a lot!!

How much whiskey will this yield?

Take a look at this comment. I think it will answer this question.

http://howtomakewhiskeyhq.com/how-to-make-whiskey-step-by-step/#comment-375

How much sugar and what’s the yield on the posted recipe? Thanks

None. However, you can double the water and add 6 lbs of sugar to get a better yield while still getting some of the corn mash flavors.

What would you define as whole untreated corn kernals. Is that dried or anything. Could I buy corn on the cob at a store and cut it off the cob?

Dried does not mean treated.

Corn can be treated with lye and other chemicals. For example, some seed companies will treat their seeds with a coating to provide give it a better chance of survival in less than optimal conditions. For example, here is a blog post from Gurney’s seed co. that talks about this…

+++++++++++++++++++++++++++++++++++

Well, folks, I’m here to dispel any predispositions you may have about treated seed. The truth is this: treated seed is a very good thing! It simply provides extra protection against less than ideal growing conditions. That means you can plant earlier without the worry of rotting seed from cold, wet early spring weather. This treatment also ensures better germination as well as enhanced resistance to soil-borne diseases and fungi.

Source: http://www.gurneysblog.com/uncategorized/treated-seed-corn-and-peas/

+++++++++++++++++++++++++++++++++++

If you want to make Hominy you can soak the dried kernels in a weak lye solution for about a week. I would say this is also a good definition of treated.

Fresh (or frozen) corn. Yes. You can go that route too. I will try to post a recipe for doing this. I will of course need to test a few out myself to find one I like.

For untreated corn kernels check with a local feed store. They should have what you need. You can also look at farmers market. Another option would be to find dried corn on the cob and remove the kernels yourself.